Leather

Premium Leather Selection for Our Notebooks

At The Horse Notebooks, leather isn’t just a component—it’s the heart of our notebooks. Therefore, we meticulously select only the finest leather available, ensuring each notebook we produce exudes quality and sophistication.

Our Leather Choice

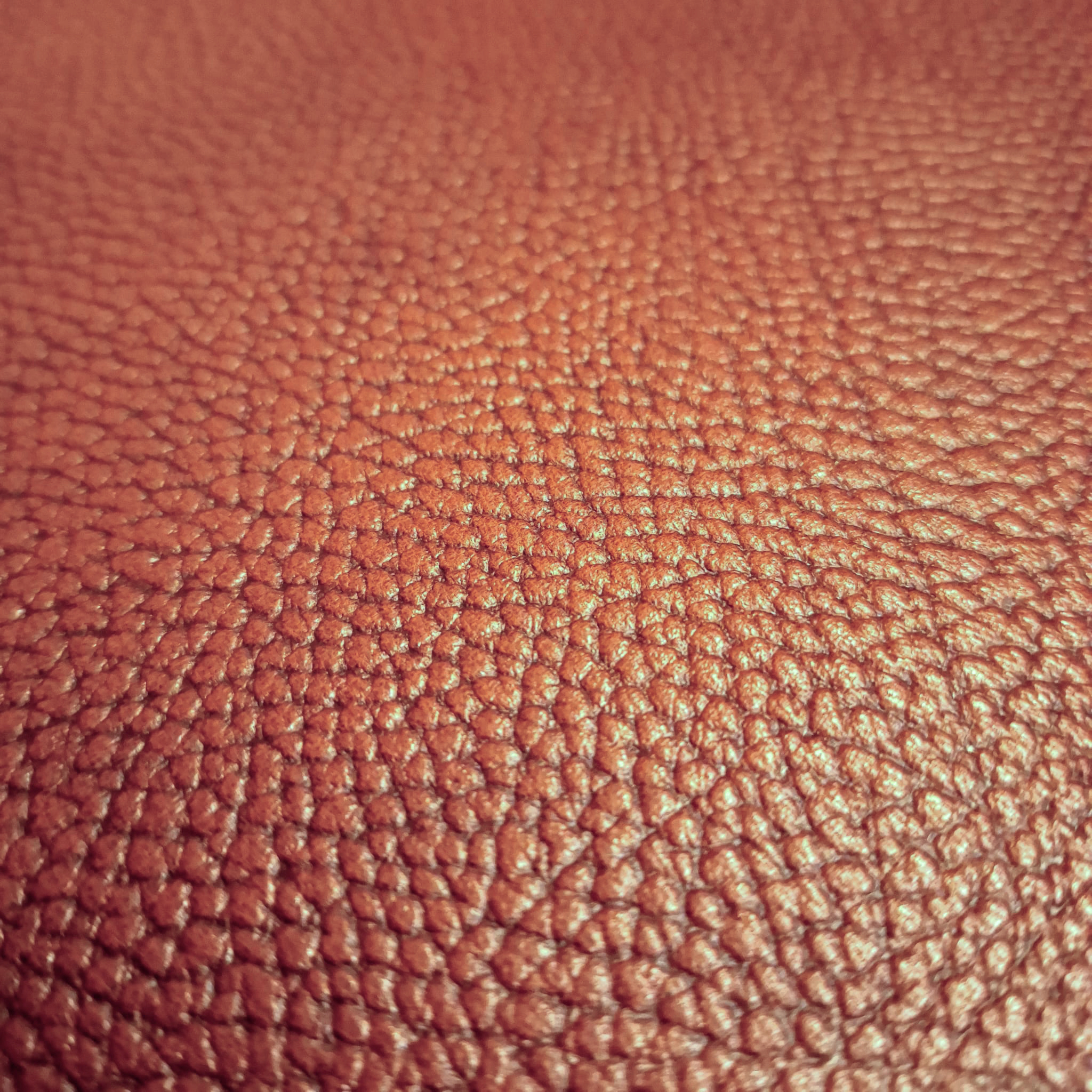

We source our leather from the most reputable tanneries across Europe, including those in the Netherlands, Turkey, France, and Italy. After extensive evaluation, we chose calf and goat skins with a vegetable-tanned shoulder leather known for its unparalleled quality.

Calf-skin Leather

This leather is vegetable-tanned, treated naturally, and has a distinct grain that varies within each hide. The process involves soaking the hides in a mixture of tree bark and trunk extracts, followed by greasing with animal fats and drum dyeing. Consequently, this gives the leather a rich, deep color that can be enhanced further by burnishing with a dry cloth. As a result, the leather is both durable and beautiful, with each piece being unique in its grain structure. Produced by the esteemed Badalassi Carlo tannery in Italy, this leather is a true testament to superior craftsmanship.

Key Properties:

Finish: Matte with natural oils

Feel: Medium handle with a natural grain

Thickness: 1.5/1.7mm

Tannage: Vegetable

Origin: Italy

Goat-skin Leather

Chèvre Liégée-Main is a premium leather renowned for its exceptional quality and noble natural tanning process, which combines vegetable tanning with either aniline or pigmented finishes. The leather features a beautiful, distinctive grain, available in either a russet round or long grain pattern. Each skin ranges in size from 0.45 to 0.65 square meters, with a thickness of 0.9 to 1.1 mm. This exquisite leather showcases a perfect balance of durability and elegance, making it ideal for high-end leather goods.

Key Properties:

Finish: Matte with natural oils

Feel: Medium handle with a natural grain

Thickness: 0.9 / 1.1 mm

Tannage: Vegetable

Origin: France

Each hide used in our notebooks tells its own story, with varying grain patterns that add character and uniqueness to every product.

Our Leather Processing Technique

Selecting premium leather is only the first step. However, the real craftsmanship begins when we receive the leather as 0.45 to 0.65 M² skins. Here’s how we transform raw hides into exquisite notebook covers:

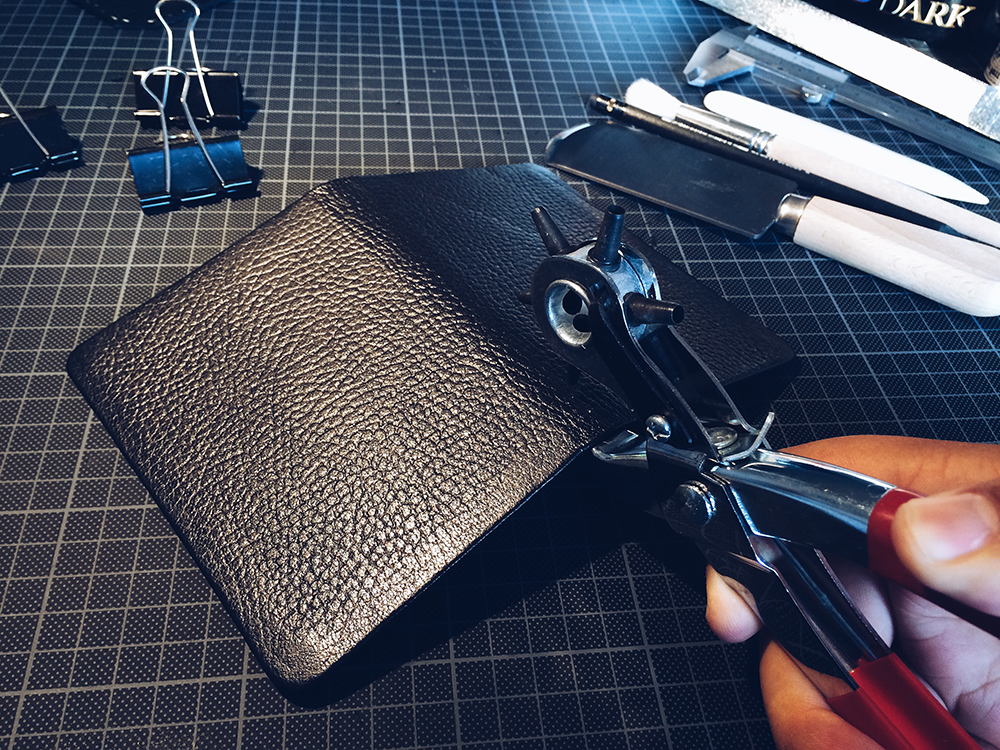

Cutting the leather

The first crucial step in our leather processing technique is precision cutting. When the leather arrives at our workshop, it is in its raw, uncut form, typically measuring between 0.45 to 0.65 M² per skin. At this stage, the leather retains all its natural characteristics, including any variations in grain, texture, and thickness. These characteristics are what give our notebooks their unique appeal, so we treat this material with the utmost care.

We start by carefully measuring and cutting the leather to the specific dimensions required for our notebooks. However, precision cutting is not merely about ensuring the leather fits the notebook. It involves a strategic process where we leave an extra margin of leather around the edges. This excess margin is essential for the subsequent paring process, allowing for adjustments and ensuring that the leather cover perfectly aligns with the notebook’s final size.

Moreover, during cutting, we pay close attention to the leather’s grain direction and any natural marks or scars that may be present. These elements can influence the leather’s appearance and performance. By skillfully selecting which parts of the hide to use, we can emphasize the leather’s natural beauty while ensuring that the finished product is durable and functional. The precision cutting process requires not only sharp tools but also a deep understanding of leather as a living material. It is a blend of art and science that sets the foundation for the flawless finish we strive to achieve.

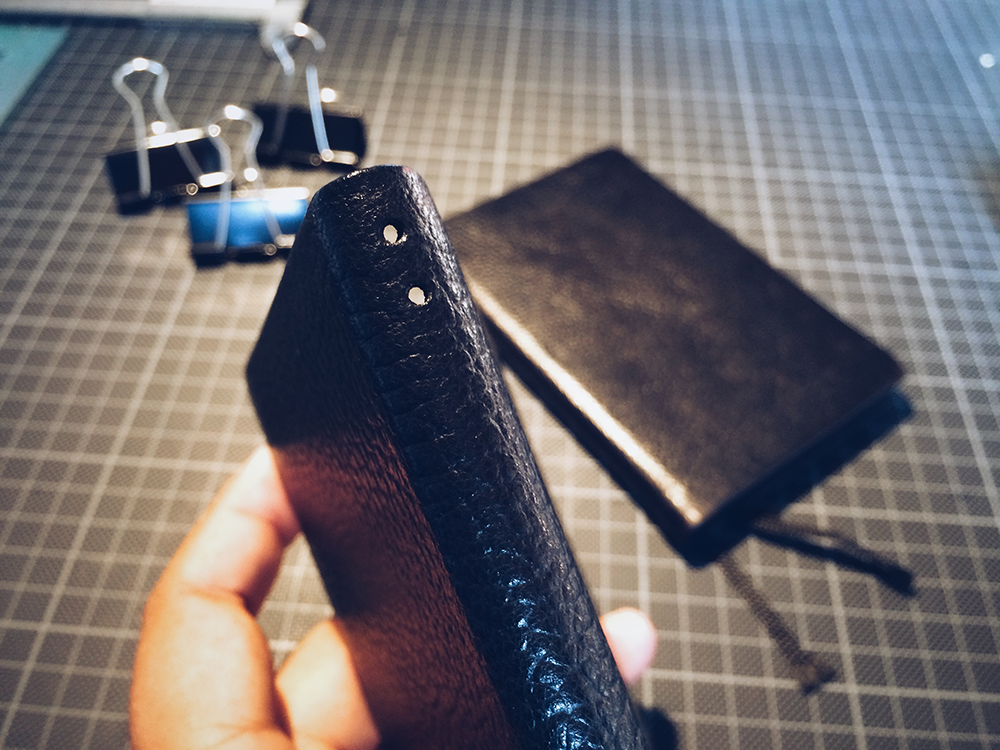

Paring and Skiving the Leather

Once the leather has been cut to size, the next step is paring. Paring the leather is a delicate and highly skilled process, where the leather is meticulously thinned down. This step is essential to create a seamless transition between the leather and the surface it adheres to, whether that be the inner lining or the museum-quality cardboard we use for our notebook covers.

The objective of paring is to “get to zero,” which means there should be no noticeable difference in height or texture between the leather and its adjoining surfaces. Achieving this requires an experienced hand and a keen eye. The leather must be thinned evenly across its surface, particularly around the edges, to avoid any lumps or irregularities that could detract from the notebook’s final appearance. The aim is to create a smooth, even surface that feels natural to the touch and allows the leather to lay perfectly flat when glued to the notebook cover.

In addition, paring also affects how the leather behaves when it is folded or bent. Properly pared leather will have the right flexibility and pliability, ensuring that it does not crack or crease over time. This is particularly important for notebook covers, which must withstand regular handling while maintaining their aesthetic appeal. A poorly pared leather might result in a cover that looks and feels bulky or uneven, which is something we absolutely avoid in our bindery.

Paring/Skiving Tools

To achieve the level of precision required in the paring process, we rely on traditional tools that have been perfected over centuries. Specifically, we use a French leather paring knife, which is renowned for its ability to produce a smooth, even cut. The choice of tool is critical because it directly impacts the quality of the paring. While machines and scalpels are available, they do not offer the same level of control or finesse as a hand-held knife.

The French leather paring knife is designed to be extremely sharp and versatile, allowing our artisans to pare the leather with incredible accuracy. The knife’s blade is finely honed to a specific angle that makes it ideal for thinning leather without tearing or gouging. This tool enables us to work with the leather in a way that respects its natural properties while achieving the desired thinness.

Furthermore, the use of a traditional knife requires a high degree of skill. We must maintain a steady hand and consistent pressure to avoid any inconsistencies in the leather’s thickness. This process is done by feel and intuition, honed by years of experience, rather than by automated machines that may lack the subtlety needed for such a task. The result is a finely pared leather that is perfectly suited for the next stages of notebook production.

Quality Control

After the leather has been pared to perfection, the next step in our process is rigorous quality control. This stage is crucial because even the slightest imperfection can affect the final product. We meticulously inspect each piece of leather to ensure it meets our exacting standards before it moves on to the next phase of production.

During quality control, we examine the leather for any inconsistencies in thickness, texture, and overall appearance. Our craftsmen check for uniformity in the paring and ensure that the leather has a smooth, even surface free of lumps, bumps, or irregularities. This attention to detail is what sets The Horse Notebooks apart from mass-produced alternatives. We believe that every notebook should not only be functional but also a piece of art, and that requires perfection at every stage of the process.

In addition to checking the physical properties of the leather, we also assess its aesthetic qualities. The leather’s color, grain, and natural markings are evaluated to ensure they align with the high standards our customers expect. If any piece of leather does not meet our criteria, it is set aside and not used in the final product. We take pride in the consistency and quality of our notebooks, and that begins with our stringent quality control process.

Once a piece of leather has passed inspection, we emboss our signature Horse logo onto the backside. This logo is not just a mark of authenticity; it is a symbol of the craftsmanship and dedication that goes into every notebook we produce. The embossing process itself requires precision and care, ensuring that the logo is clear, well-defined, and positioned perfectly.

Gluing Process

The next step in our leather processing technique is the gluing process. After the leather has been carefully pared and inspected, it is ready to be adhered to museum-quality cardboards, which serve as the foundation for our notebook covers. The glue we use, Jade 403 PVA adhesive, is a critical component in this process. This adhesive is specifically chosen for its neutral pH, meaning it is acid-free and will not cause the leather or the cardboard to deteriorate over time.

Applying the glue requires precision and care. Too much adhesive can lead to a messy finish, while too little can cause the leather to lift or peel away from the cardboard. Our craftsmen apply the Jade 403 PVA adhesive evenly across the entire surface of the cardboard, ensuring full coverage without oversaturation. The adhesive’s flexibility when dry is particularly important, as it allows the leather to move naturally with the cover, preventing cracks or warping.

Once the glue is applied, the leather is carefully positioned on the cardboard. This step requires a steady hand and a keen eye to ensure the leather is perfectly aligned with the cardboard, with no bubbles or wrinkles. The leather is then pressed firmly onto the cardboard to create a strong, lasting bond. We take extra care to smooth out the leather, ensuring it adheres evenly and creates a flawless, seamless cover.

After the leather is glued, the cover is allowed to dry completely. This drying process is essential to ensure the adhesive sets properly and the leather remains securely attached to the cardboard. The result is a beautifully bound cover that is both durable and aesthetically pleasing, ready to be transformed into a finished notebook.

Final Touches

The final touches in our leather processing technique are what truly set The Horse Notebooks apart. After the gluing process is complete and the cover has dried, we move on to the last few steps that bring the notebook to life. First, we punch holes into the cover for the bookmarks. This step, while seemingly simple, requires precision to ensure that the holes are evenly spaced and aligned perfectly with the notebook’s spine.

Next, the cover is prepared for binding. At this stage, we carefully inspect the cover one last time to ensure it meets our quality standards. The cover is then paired with the inner pages of the notebook, which have been carefully selected and prepared in parallel with the leather processing. The binding process is where all the components come together to form the final product.

Once bound, the notebook undergoes a final inspection. We check everything from the alignment of the cover to the quality of the binding, ensuring that every aspect of the notebook meets our high standards. Only after passing this final inspection is the notebook deemed ready for sale.

Why Choose Our Notebooks?

In conclusion, the leather processing technique at The Horse Notebooks is a meticulous and detailed process that involves multiple stages of cutting, paring, quality control, gluing, and final touches. Each step is carried out with precision and care, ensuring that our notebooks are not only functional but also works of art. By using the finest leather and traditional tools, we are able to create notebooks that are both beautiful and durable, ready to be cherished for years to come.

Every notebook we create is a product of careful selection, expert craftsmanship, and a commitment to quality. The Badalassi Carlo Minerva Box leather we use guarantees a luxurious feel, durability, and unique aesthetics. Combined with our meticulous processing methods, our notebooks are not just stationery—they’re works of art designed to last a lifetime.

Therefore, experience the difference that exceptional leather and expert craftsmanship can make. Choose The Horse Notebooks for unmatched quality and elegance.

The “Royal Notes” collection epitomises luxury and sophistication, featuring handcrafted, leather-bound notebooks made with premium materials for notebook lovers.

Royal

Notes

-

Royal Notes – Prince€150.00 exl. VAT

Royal Notes – Prince€150.00 exl. VAT -

Royal Notes – Queen€200.00 exl. VAT

Royal Notes – Queen€200.00 exl. VAT -

Royal Notes – King€250.00 exl. VAT

Royal Notes – King€250.00 exl. VAT